Working as a multi-family maintenance technician involves servicing many types of appliances and systems using a wide range of strategies and methods. To be successful in the building maintenance field, it’s helpful to understand the different types of maintenance methods that there are and how and when they’re used.

Here’s a look into the most common types of maintenance and how Interplay Learning can help you learn more about them.

Preventive Maintenance

Preventive maintenance is aimed at catching and fixing problems before they happen. It is most commonly carried out in the form of regular inspections, usually occurring multiple times per year.

When you inspect a system or a piece of technology, carefully check for all signs of wear, tear or imminent breakdown. Replace damaged parts immediately. This will prevent having to go into “crisis mode” if something breaks unexpectedly.

The primary benefit of preventive maintenance is that it can eliminate unplanned shutdown time as you will ideally catch problems before they occur.

Condition-Based Maintenance

Condition-based maintenance is sometimes considered to be a more advanced alternative to preventive maintenance. Rather than being inspected according to a schedule, machines and systems are carefully observed for changes that could indicate upcoming failure.

With condition-based maintenance, technicians observe the system running and identify variables that could affect functioning, like temperature, vibration speed, power, the presence or absence of moisture, and more.

Another strategy within condition-based maintenance is predictive maintenance.

Predictive Maintenance

Predictive maintenance refers to a specific type of condition-based maintenance in which systems are constantly observed via sensor devices. These devices are attached to components of the system and feed constant, real-time data to software. The software then interprets this data and warns maintenance technicians of approaching danger.

Predictive maintenance is generally considered to be the most advanced and intensive type of maintenance. This is because there is a lot of data to interpret – and the sensor devices themselves need to be regularly maintained and checked.

Corrective Maintenance

Corrective maintenance is initiated when a problem is discovered while working on another work order. With corrective maintenance issues are caught ‘just in time’.

For example, during a scheduled maintenance check or while fixing another issue, a maintenance technician notices that a pipe in a HVAC system is not working as it should. Corrective maintenance is then scheduled for a future date where the problem is repaired or replaced.

Because corrective maintenance issues are found ‘just in time’, it reduces emergency repairs and increases employee safety.

Predetermined Maintenance

Unlike other styles, predetermined maintenance is carried out using rules and suggestions created by the original manufacturer, rather than the maintenance team. These suggestions are based on experiments and gathered data.

The manufacturer provides statistics and guidelines, usually when the equipment is first purchased and will include data providing the average lifespan of both the entire system and its various parts. The manufacturer will suggest how often parts should be inspected, serviced and replaced.

Relying solely on a predetermined schedule may risk system failures as technicians may not be able to anticipate problems. It can also cause multi-family maintenance teams to replace parts too early, resulting in additional costs. Additionally, predetermined maintenance doesn’t guarantee that a system won’t break down since the program is based on statistics and not the actual state of the equipment.

Gaining Maintenance Knowledge with Interplay Learning

Regardless of the type of maintenance strategies your team utilizes, different areas of a multi-family building must be regularly serviced in order to avoid costly repairs or extended downtime. In much the same way, the knowledge and skills of your maintenance technicians must be regularly maintained and updated so that they don’t fall behind.

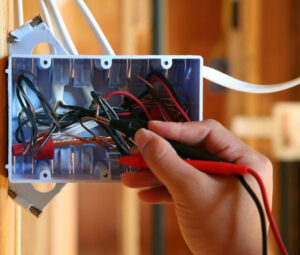

You can avoid that problem with ongoing property maintenance training provided by Interplay Learning’s online course catalogs. Interplay’s digital training approach uses 3D and virtual reality (VR) based technology to create hands-on lessons and simulations which can be practiced by technicians from absolutely anywhere.

Whether your team needs to brush up in areas of electrical systems, plumbing, or HVAC, they’ll to learn using the methods that work best for them.

Interested in learning more about Interplay Learning’s facility maintenance course?