Facility leaders know that well-trained maintenance teams are the backbone of operational performance. Whether you manage a single site or an entire portfolio, the right training program ensures your technicians can work safely, minimize downtime, and keep critical systems running efficiently.

There are several types of training available for commercial building maintenance teams, including on-the-job learning, video-based programs, and simulation-based training. Each format supports different learning needs, from foundational skills to advanced troubleshooting, and together they help you build a confident, capable workforce that drives measurable impact.

What Types of Training Are Available for Commercial Building Maintenance Teams?

1. Video-Based or On-Demand Courses

Video-based and on-demand courses allow maintenance teams to learn at their own pace, anywhere and anytime. This flexibility is ideal for large organizations or shift-based teams. Learners can revisit modules as needed, and consistent content ensures standardized instruction across sites.

The tradeoff is that these courses are typically self-guided, offering limited interactivity or feedback. Without hands-on practice or instructor engagement, it can be harder to confirm skill application in the field.

2. Simulation-Based Training

Simulation and VR training, like what Interplay Learning offers, immerses learners in realistic maintenance scenarios where they can safely practice diagnosing problems and testing repairs. This learning method excels at building confidence and muscle memory, especially for high-risk or rare situations that can’t easily be recreated in real life. It allows for repetition, experimentation, and performance tracking.

3. On-the-Job and Mentorship Programs

On-the-job and mentorship programs give technicians the chance to learn directly within their facility environment, under the guidance of experienced peers. This format promotes real-world understanding, team cohesion, and contextual learning tied to actual systems.

However, outcomes can vary depending on the mentor’s availability and teaching style. Without a structured framework, there’s also a risk that informal learning can miss important technical or safety details.

How Does Commercial Building Maintenance Training Improve Building Performance

Investing in structured, high-quality training delivers measurable operational and business results:

- Reduced downtime: Faster, more accurate troubleshooting minimizes disruptions.

- Improved energy efficiency: Properly calibrated systems lower utility costs.

- Enhanced safety: Consistent adherence to procedures reduces incident risk.

- Higher retention: Skilled employees feel confident and engaged in their roles.

- Better asset performance: Regular, informed maintenance extends equipment life.

The Growing Role of Simulation and Digital Learning in Maintenance Training

Most facilities already have some form of training in place, whether it’s safety briefings, classroom instruction, or on-the-job mentorship. These approaches remain valuable and familiar to teams. But as building systems evolve, the impact of those traditional methods multiplies when combined with modern digital tools.

By integrating simulation-based learning, on-demand video, and on-the-job training into a single blended program, organizations can turn routine training into continuous skill development. This approach reinforces what technicians learn in the classroom through hands-on digital practice, closing the gap between knowledge and performance in the field.

- Safe, repeatable practice: Learn complex or hazardous procedures in risk-free virtual environments.

- Visual understanding: See how systems interact and respond to faults in real time.

- Consistent delivery: Ensure every technician receives the same high-quality instruction.

- Actionable insights: Track progress and performance through detailed learning analytics.

At Interplay Learning, we combine video-based courses and immersive simulations into a unified platform. This blended approach helps commercial maintenance teams build confidence, improve safety, and keep facilities performing at their best.

Ready to Strengthen Your Team’s Skills?

Explore how Interplay Learning’s digital and simulation-based training helps facilities teams build technical confidence, reduce downtime, and keep buildings running smoothly. Whether you’re upskilling new hires or advancing experienced technicians, our platform makes it easy to deliver consistent, engaging training that drives measurable results.

Frequently Asked Questions

Maintenance training for commercial buildings is available through a mix of online training platforms, local trade schools, and employer-sponsored programs. Many organizations now use digital and simulation-based training to provide realistic, hands-on practice without disrupting operations. Interplay Learning offers on-demand, simulation-based training designed to help maintenance teams build real-world skills safely and efficiently.

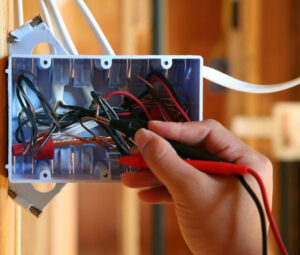

Maintenance professionals need a broad foundation of technical and soft skills. Core technical areas include HVAC, electrical, plumbing, mechanical systems, and building automation. Beyond technical knowledge, strong problem-solving, communication, safety awareness, and documentation skills are essential to ensure reliability and compliance across all building systems.

Training length depends on the program type and desired skill level. Foundational courses can take a few hours, while advanced or certification-level training may span several weeks or months. Many organizations now use continuous learning models, combining short, on-demand courses with ongoing simulation practice to keep skills current over time.

The most effective approach is a blended one – combining video-based instruction, simulation-based learning, and on-the-job experience. Digital and simulation training reinforce real-world problem solving, while hands-on work builds confidence and muscle memory. Together, these methods create a scalable and sustainable way for facilities teams to strengthen technical skills and improve building performance.