As part of the Federal Clean Air Act, the EPA 608 Certification is required for any technician who maintains, services, repairs, or disposes of appliances that contain regulated refrigerants. The good news about the EPA 608 certification is that it’s a one-time test, with no expiration and no requirement for renewal.

Additionally, having in-depth knowledge about refrigerants and the refrigerant cycle, as an HVAC technician, can help to advance your career — as it is the backbone of the industry.

Here is everything you need to know about the 608 certification.

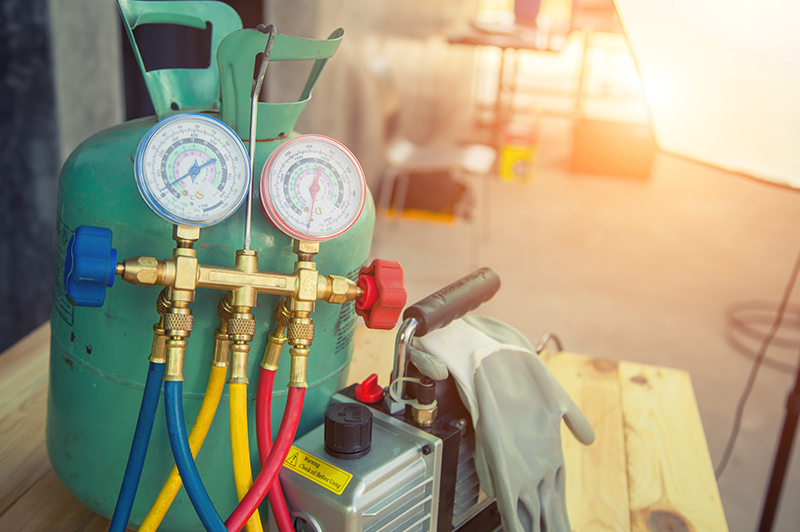

You’ll Need Knowledge of Refrigerants

There are two refrigerants that are tightly regulated by the EPA and are especially important to understand for the 608 certification.

R-22

Formally known as chlorofluoromethane, R-22 was a replacement for CFC-11 and CFC-12, thanks to its lower ozone depletion potential. Today, however, R-22 is considered too damaging to the ozone to stay in use. It’s a powerful greenhouse gas, with nearly 2,000 times the global warming potential of CO2.

The diminishment of this refrigerant started in 2004 and it has since been phased out worldwide. Many systems have been retrofitted to use R-407A, R-407C, R-424A, and other replacements.

R-410A

Sometimes known by its brand name of Puron, R-410A is less damaging to the environment than R-22 and is a far more efficient refrigerant. Systems that use R-410A also run on synthetic oil rather than mineral oil, and as a result the compressor can run cooler. The enhanced efficiency of the system means a lower utility bill for the owner. It’s also designed to operate at a much higher pressure than older units that used Freon refrigerants.

When it was learned that Freon was a pollutant, the EPA began regulating the use and handling of these refrigerants, as part of the Federal Clean Air Act.

The Clean Air Act

Enacted in the early 60s, the Federal Clean Air Act is some of the earliest legislation to improve air quality. Over the years, it has been amended to include car exhaust, acid rain, aerosols, and other pollutants, including Freon. The long-term goal is to phase out ozone-depleting refrigerants and replace them with ozone-friendly ones. The EPA 608 Certification takes its name from Section 608 of the Clean Air Act, which states:

“EPA regulations (40 CFR Part 82, Subpart F) under Section 608 of the Clean Air Act require that technicians who maintain, service, repair, or dispose of equipment that could release ozone-depleting refrigerants into the atmosphere must be certified.”

What To Expect With The EPA 608 Certification

Improper handling of refrigerants can damage the systems you’re servicing, and the danger is even greater in multi-family, commercial and industrial HVAC systems as the systems are designed with extremely high pressure. This is why the EPA 608 certification is something you need to take seriously; not just for environmental concerns, but for your own safety.

There are four different types of 608 certifications you can acquire and each depends on what type of HVAC service you’ll be doing. But first, you’ll need to pass the “Core Section” of the EPA exam, which is considered essential for any work with refrigerants.

The Core Section

The Core Section covers general principles and the reasons why HVAC is so highly regulated. The section includes the following topics:

- Ozone depletion

- Clean Air Act

- Section 608 regulations

- Substitute refrigerants and oils

- Refrigeration

- The Three R’s: Recover, Recycle, Reclaim

- Recovery techniques

- Dehydration evacuation

- Safety

- Shipping

You can prepare for this section of the exam with this online core prep course.

Four Types of EPA 608 Certification

While every technician is required to pass the Core Section of the exam, there are four different types of the 608 certification that correspond with the specific kinds of appliances that will be serviced.

Type I

The Type I EPA certification is specifically for servicing small appliances. The exam is open-book and covers recovery requirements, safety, and recovery techniques. You’ll be required to get 21 of 25 answers right, along with the Core Section discussed above. You can take the Core Section open-book exam to obtain the Type I certification, but you’ll have to retake it (closed-book) for any certifications above Type I. If you’re tired of reading about these topics, you can study with interactive videos in this Type I prep course.

The “small appliance” category is for things like refrigerators, and you will need to know:

- Evacuation requirements for appliances with or without functioning compressors

- Knowledge of pressure and temperature to indicate the type of refrigerant used

- Recovery methods, such as system-dependent recovery, and the proper use of high- and low-side access valves for recovery on an appliance with a dead compressor

- Operative compressors, solderless access fittings, and decomposition products of refrigerants

Type II

The Type II exam covers high-pressure or very high-pressure systems, excluding automotive AC and small appliances. This test has a greater focus on leak detection but also involves recovery techniques and requirements. There will be 25 questions that cover the following topics:

- Right ways to check for signs of leakage and how to perform a leak test before charging a system

- Annual leak rate for commercial/industrial refrigeration and systems that hold more than 50 pounds of refrigerant

- Recovery techniques and requirements

- How to handle emissions during the recovery process and minimize cross-contamination

- Recovery requirements for disposal, repairs, and leaks for these systems.

- The identification of the main components of a high-pressure system

- Where the refrigerant is located in the system and how to perform the pressure/temperature test

Check out this Type II prep course that covers everything you need to know so you can be confident when you take the closed-book exam.

Type III

The Type III EPA certification will cover servicing or disposal of low-pressure appliances, as well as, leak detection, leak repair requirements, recovery techniques and requirements, and refrigeration. While this might seem like it’s duplicating much of Type II requirements, the design of low-pressure systems is quite a bit different. You can learn more about these differences (and the following topics) by studying with this interactive Type III prep course. The additional things you’ll need to know for the exam include:

- Signs of leakage

- Maximum leak test pressure for centrifugal chillers

- How to identify and repair leakage in these systems

- Evacuation requirements

- Knowing what constitutes a “major repair”

- ASHRAE Standard 15 requirements

Universal

Once you’ve passed Type I, Type II and Type III requirements, you’ll be eligible for the Universal Certification. This comprehensive test is 100 questions covering a combination of topics from the other three exams.

How to Prepare for the EPA 608 Certification

Whether you are working as an apprentice under a seasoned HVAC technician or you’re new to the industry, getting the EPA 608 Certification is vital for working with everything from home refrigerators to multi-family building maintenance. Luckily with Interplay Learning, preparing for the exam can be easy.

Unlike other training programs that put the emphasis on study guides, texts, and workbooks, Interplay Learning offers additional ways of learning with virtual reality and animation that puts you a lot closer to real-world scenarios. The beauty of Interplay’s online HVAC training is that you can watch the videos and take the courses on your phone, laptop, tablet or other devices, wherever you are and whenever you want.

Interplay Learning also offers continued learning courses, so once you’ve passed the EPA 608 Certification, they can help you become a seasoned veteran in the field.