For decades, unions and trade associations have trained world-class tradespeople through hands-on training and rigorous skill development. But with younger generations entering the workforce, they face a critical question: How can they preserve proven training methods while meeting demand for new technology? At the same time, how can they attract new members and scale training programs?

Simulation-based training is one way to bridge this gap. Still skeptical? Let’s address common concerns head-on and explore how forward-thinking unions like IUOE Local 94 are already seeing results.

Types of Simulation-Based Training for the Trades

First, let’s define the most common types of simulation-based training you’ll encounter.

- 3D simulations are computer-based interactive environments where users explore and engage with virtual representations of objects, systems, or scenarios in three dimensions.

- Virtual reality (VR) simulations are fully immersive, interactive virtual environments made possible through VR headsets. VR simulations are built with 3D simulations, but are a more immersive way to interact with 3D simulations due to the VR headset.

4 Myths About Simulation-Based Training

While simulations are relatively new to the trades, professionals like surgeons and pilots have been effectively taking advantage of this technology for decades. It’s time that the trades reap the benefits of these tools as well.

By practicing in a simulated environment, learners can hone their skills, make mistakes in a low-stakes environment, and ultimately be more prepared for real scenarios. For example, one study found that learners felt 275% more confident in applying skills after training with VR compared to traditional methods of training.

But are you ready to make the leap from physical simulations to virtual ones? Here are four of the top misconceptions about 3D and VR simulations and the truth according to leaders who have adopted them.

Myth #1: “Virtual simulations can’t replace hands-on practice.”

It’s natural to question whether virtual simulations are as effective as physical ones, since you can’t touch and feel the equipment.

Reality: Simulations complement hands-on practice with enhanced practice, confidence, and safety.

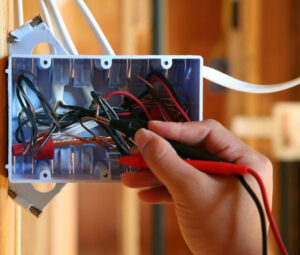

Simulations replicate the complexity of real-world job sites, allowing learners to build confidence in a virtual environment before attempting high-risk tasks, such as electrical work, in physical settings. This interactive approach serves as an effective stepping stone between theoretical knowledge and hands-on practice, ultimately making time spent on actual lab equipment more productive and efficient.

Simulations also engage the part of a learner’s brain that learns by doing, helping them learn more effectively. In fact, research has shown that VR learners are 3.75 times more emotionally connected to their training compared to classroom learners. Simulations offer a way to get learners hands-on earlier in the training process without the safety risks that come with practicing on real equipment.

Myth #2: “We can’t trust that the content is accurate.”

You may also wonder if the technical content is 100% accurate and up-to-date with industry standards.

Reality: High-quality programs align simulations to current industry standards.

A good vendor will ensure that simulations are developed by subject matter experts and updated rigorously to industry standards. Look for a provider with industry-recognized credentials and certifications, like NATE, ANSI/IACET, OSHA, or HVAC Excellence. You can also ask providers to show how their content maps to your curriculum or industry-recognized standards, such as NCCER, to see if they can demonstrate their alignment.

Myth #3: “Our members won’t adapt to this technology.”

With an average age of 43 and a sizable digital skills gap in the trades, members might be unwilling to adopt an unfamiliar learning format.

Reality: Simulation-based learning engages all generations and attracts younger learners.

Simulations engage learners on multiple sensory levels (auditory, visual, and kinesthetic) and resemble the tech used in our everyday lives, like video games. It can also attract vital young members to your association.

Dave Hawkins, Training Director at IUOE Local Union 94 in New York City, shared how his members responded to an Interplay Learning 3D simulation program introduced to prepare them for upcoming licensing exams. “It deeply enriched our traditional learning materials with visuals, significantly enhancing engagement, retention, and enjoyment in the learning process,” said Hawkins.

Myth #4: “Fancy tech is out of our budget.”

Lack of financial resources is the second most-cited reason trade unions avoid educational technology, according to ETUI.

Reality: Simulations can help trade unions scale training while saving on other costs.

Most unions and trade associations see a simulation-based platform as an extra line item, adding to their costs. While there is a licensing fee, the key is to look beyond it to see how the tech reduces costs on other line items. For example, by starting some or all of your learners on simulations, you can reduce the need for equipment, lab space, and consumables.

It can also help you expand the number of members you can serve, removing restrictions due to physical space, as well as reduce safety incidents which come with their own costs. With these savings, cutting-edge technology is more accessible than you think.

Scale Up with Simulation-Based Training

Unions don’t need to choose between tradition and innovation. As Hawkins shares: “The impact of Interplay on our program’s first few cohorts has been outstanding. The program’s flexibility allows members to train on their own time and at their own pace. Members who actively engage with Interplay consistently demonstrate a deeper understanding of the material, and we’ve seen a significant increase in pass rates for the licensing exam.” By blending simulations with tried-and-true physical learning environments, you can:

- Safeguard proven training legacies.

- Improve retention and pass rates.

- Reduce costs and safety risks.

- Engage a new generation of members.

With 3D simulations, unions can lead the way in this once-in-a-generation shift of modernizing the trades education.