White paper

Why Smart Facilities Go Proactive

Comparing the Cost of Reactive vs. Preventive Maintenance

Why Prevention Starts with Skilled Technicians

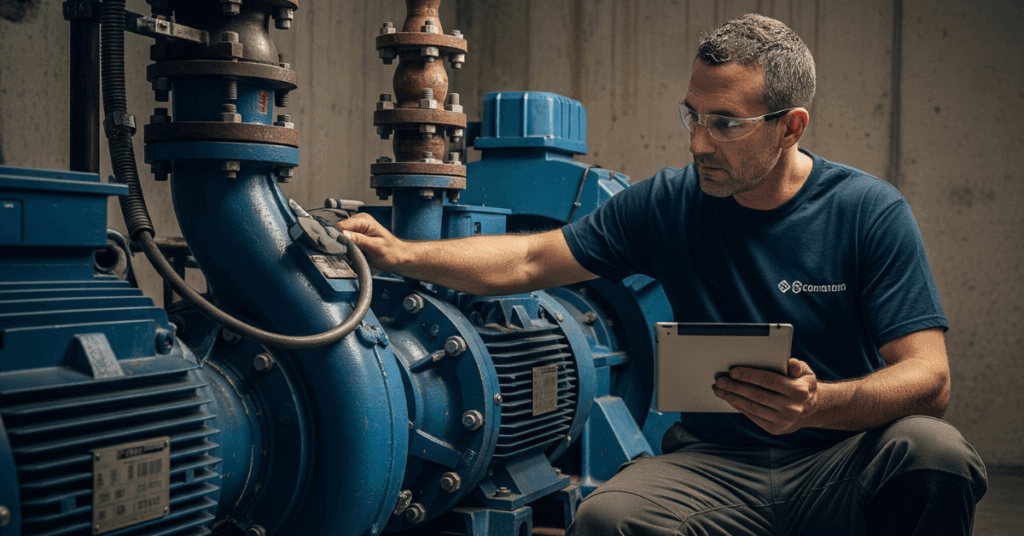

Unplanned breakdowns don’t just drain budgets; they can create chaos. From emergency service calls to technician burnout and safety risks, reactive maintenance can put a heavy strain on operations. While the cost of reacting is undeniable, effective prevention goes beyond just tweaking schedules. It demands a highly skilled and confident workforce. With the right training strategy, your team can proactively identify issues, respond swiftly to challenges, and minimize costly disruptions before they escalate.

This white paper explores how a proactive maintenance strategy helps facilities teams lower costs, increase uptime, and run more efficiently, all while giving technicians the skills to fix issues correctly the first time. Whether you’re improving your current approach or starting from scratch, this white paper offers practical steps to save money and take control of your maintenance program.

You’ll gain insights into:

The real, often hidden, costs of reactive maintenance

How preventive maintenance improves budget predictability, uptime, and energy use

The ways blended learning helps your technicians diagnose and solve problems faster